Did you know it is imperative to regularly check many elements of your forks, to ensure that they comply with regulations and are safe for use. There are many ways to do this, and having a fork wear caliper will be very useful if not essential.

Our very own Emma had filmed a video which explains how our Fork Safety Calliper Guide Kit can help you check your forks and ensure you are complying with the industry regulations.

Take a look through the steps below, to make sure you are always operating safely:

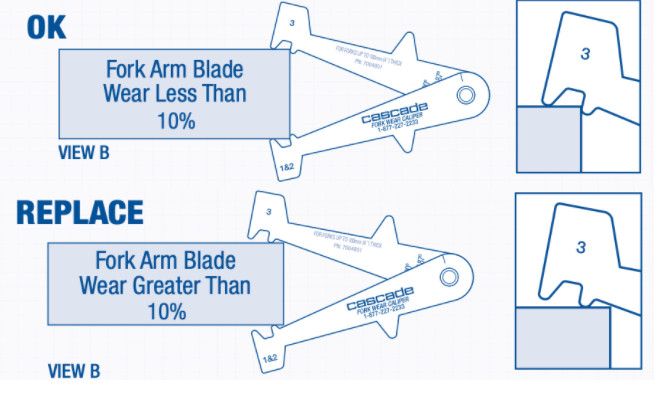

Check the fork wear

-

Start by measuring the thickness of the shank with the teeth of the caliper.

-

Once you have this reading, keep the caliper position in place and place the same teeth of the caliper over the fork arm blade.

-

If any part of the caliper back teeth make contact with the blade, then it has less than 10% wear and it can continue to be used.

-

However if these back teeth move freely over the blade, over 10% wear has occurred with a 20% reduction in strength, therefore the fork arm should be taken out of service.

-

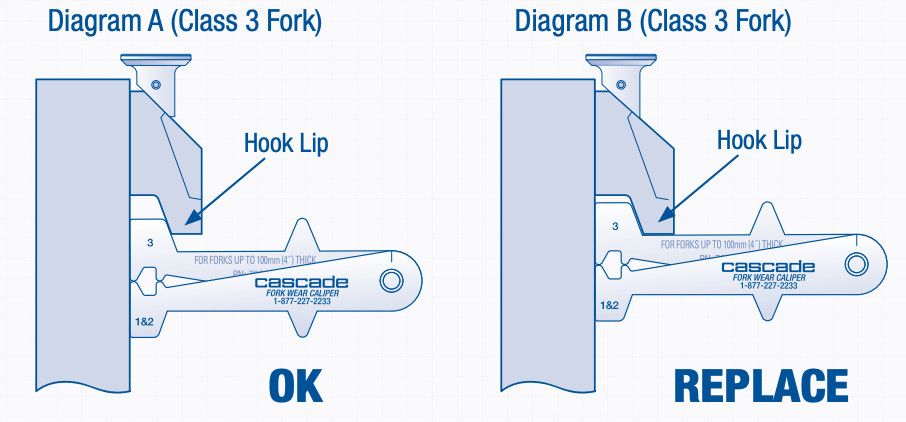

Assess the fork hooks

-

With the caliper closed, place the end of it into the hook pocket.

-

If the hook lip makes contact with the back of the caliper, the fork should be removed from service.

-

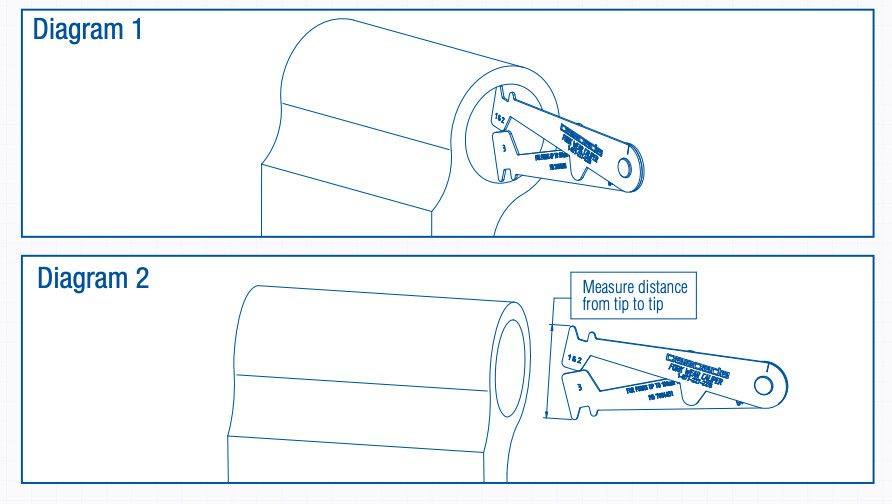

Measure the bore or bushing on shaft/ pin type forks

-

Reverse the caliper and insert this into the bore or bushing, then open the teeth until both sides come in contact with the inside walls.

-

Pull out caliper and measure the tip to tip then check this with the fork manufacturer requirements, to see if this measurement is appropriate.

-

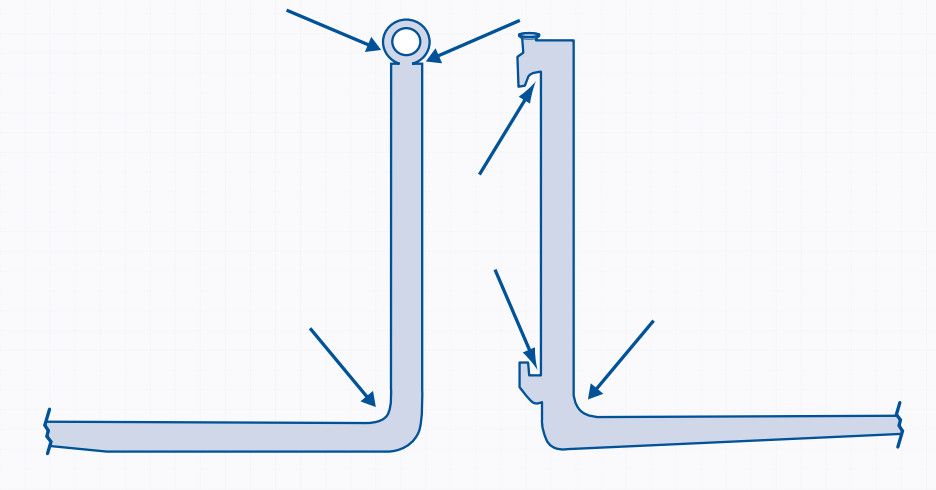

Identify any surface cracks

-

Make sure to extensively inspect the fork heel and all welds, for if there are any surface cracks the forks cannot be used for service.

-

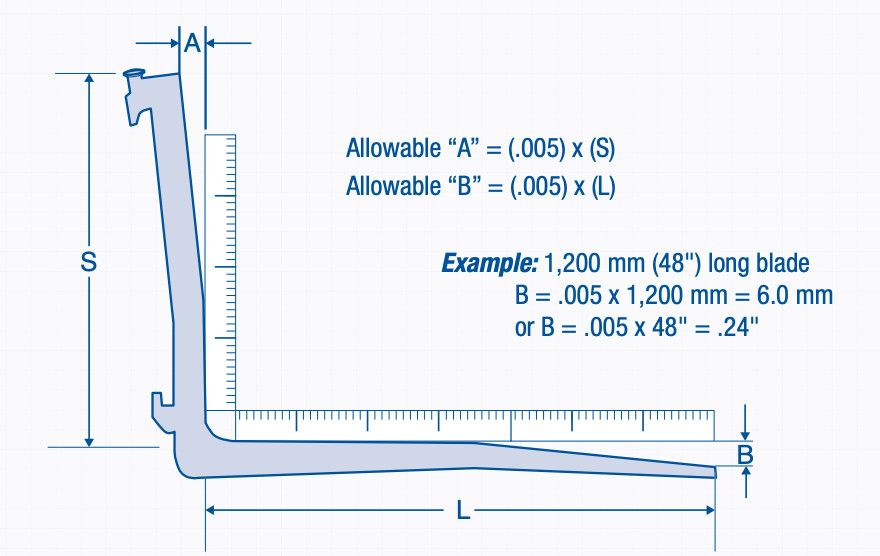

Assess the straightness of the blade and shank

-

Both the blade and the shank need to be within .005 x their length

-

If they exceed this angle they should not be returned to service until repaired

-

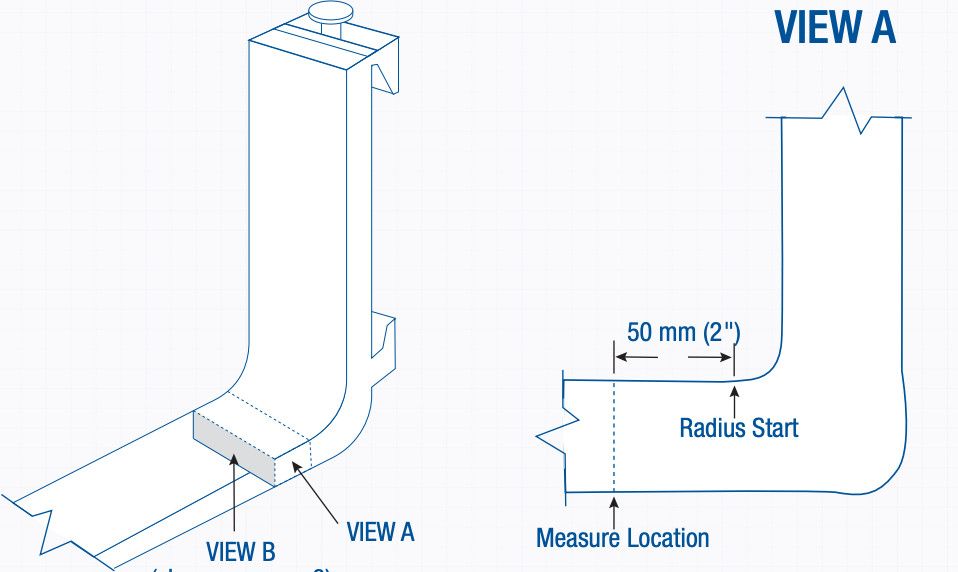

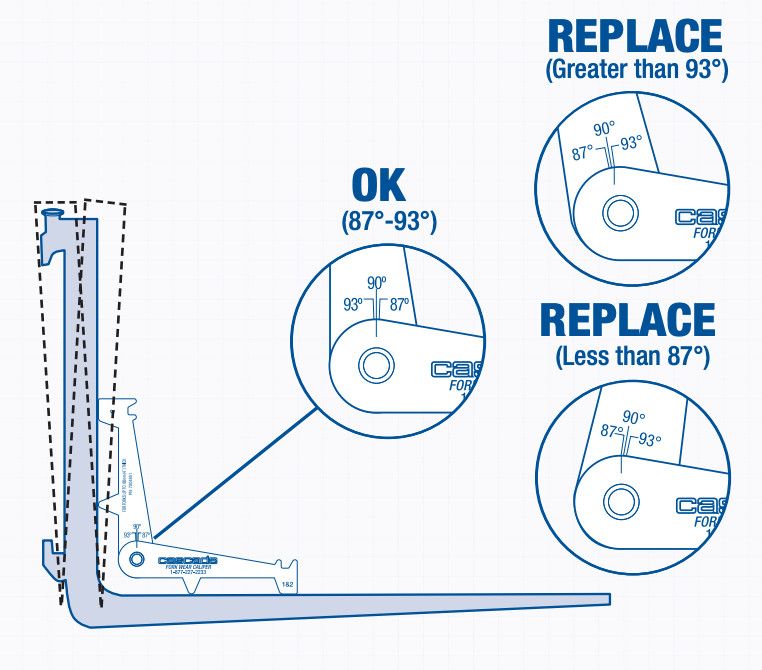

Measure the angle of the blade to shank

-

You can open up the caliper to measure this angle

-

If the angle exceeds 3 degrees more or less than 90 degrees, the fork is not safe for service.

-

So between 87-93 degrees is the fork is able to function effectively

-

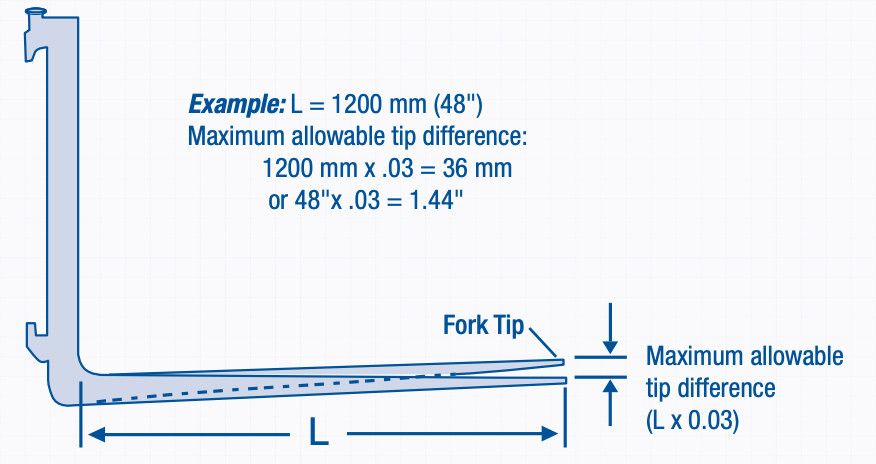

Assess the alignment of the fork tips

-

If a pair of forks on the same carriage exceed 3% of the blade length then these are not fit for service

-

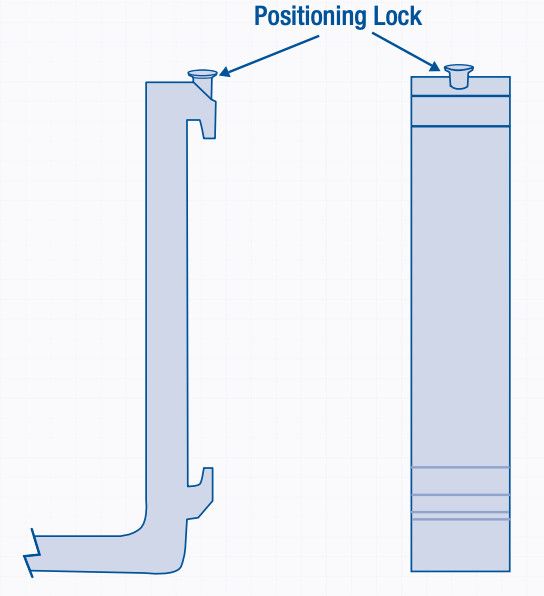

Check the positioning lock

-

If this is absent or non-operational then the forks cannot be used

-

In following each of these steps on a regular basis, you can ensure you’re always in safe hands with your machinery, and it will be highlighted if perhaps repairs or new parts are needed.

The fork wear caliper and full instructions and details of how to check and use your forks are in stock as our Fork Safety Guide on our website at: https://www.htsspares.com/catalogue/plant/telehandler-parts/jcb-style-telehandler-parts/show/fork-safety-calliper-guide-kit-0