JCB has taken significant steps in developing hydrogen-powered engines, positioning itself as a leader in the commercial application of this technology. Spearheaded by Chairman Anthony Bamford, JCB's £100 million hydrogen project aims to create efficient and scalable hydrogen engines for various applications. Let us explain how it all works...

JCB's hydrogen engine operates using hydrogen gas in a modified internal combustion engine. Hydrogen is stored in a high-pressure, robust, and well-insulated tank. The fuel injection system introduces hydrogen gas into the combustion chamber using specially designed injectors to handle hydrogen's unique properties.

The air intake system mixes air with hydrogen in the correct ratio for efficient combustion. This mixture enters the combustion cylinders, where spark plugs ignite it, causing combustion and generating high-pressure gas that drives the pistons. The expansion of hot gases pushes the pistons down, turning the crankshaft, which powers the vehicle or machinery. The primary byproduct is water vapour, resulting in no carbon emissions and making it an environmentally friendly alternative to traditional fuels.

JCB’s hydrogen engine has several advantages. It produces zero carbon emissions, as hydrogen combustion results only in water vapour. This eliminates harmful emissions and leverages existing internal combustion engine technology, simplifying adaptation for hydrogen use. Additionally, hydrogen engines can achieve high thermal efficiency due to the high energy content of hydrogen fuel.

However, challenges include hydrogen storage and transportation, which require specialised tanks and safety measures. Producing hydrogen, especially through electrolysis, is currently expensive, and reducing production costs is essential for widespread adoption. Developing robust infrastructure for hydrogen refuelling is also crucial, including establishing refuelling stations and ensuring safe transportation and handling of hydrogen fuel.

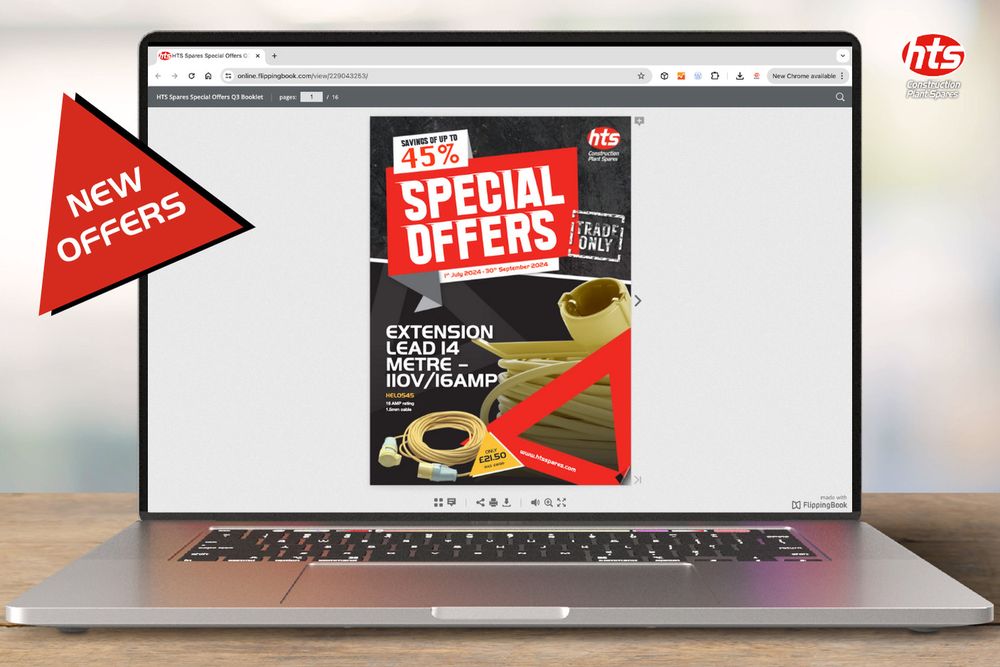

In summary, JCB's hydrogen engine burns hydrogen gas in a modified internal combustion engine, combining hydrogen with air and igniting it with spark plugs to produce power. The main output is water vapour, making it a clean energy solution. By using hydrogen combustion technology, JCB aims to provide an environmentally friendly alternative to traditional diesel and gasoline engines while leveraging existing technologies and infrastructure. Overcoming refuelling, transportation, and production cost challenges, hydrogen engines could play a crucial role in the future of green machinery technology. Meanwhile, we stock a full range of diesel parts for JCB machinery, including pumps, sender units, hose assemblies, and sensors.

At a glance...

- JCB’s hydrogen engine burns hydrogen gas in a modified internal combustion engine.

- Combines hydrogen with air and ignites it with spark plugs to produce power.

- Main output is water vapour, making it a clean energy solution.

- Aims to provide an environmentally friendly alternative to diesel and gasoline engines.

- Utilises existing technologies and infrastructure for easier adaptation.

- Challenges to overcome: refuelling, green hydrogen creation production costs and transportation.