As the year draws to a close and your hire equipment is being returned or construction projects pausing, now is an essential time for thorough cleaning and maintenance of your machines, to maintain their longevity and optimal health.

Looking after your machines now is cheaper than replacing them later.

Amidst the dust, grime, and debris that accumulate whilst construction machinery is being used, the significance of pressure washing equipment becomes paramount. Let's explore the pivotal importance of pressure washing in maintaining construction equipment and ensuring optimal functionality:

Maintenance for Longevity

Construction equipment, from telehandlers to dumpers, operates under demanding conditions, accumulating layers of dirt, grease, and residue. Regular maintenance is key to ensuring these machines operate at peak efficiency. Pressure washing offers a thorough and efficient method to remove hardened debris and contaminants that can compromise the performance and longevity of your equipment

Preventing Corrosion and Damage

Exposed to diverse weather conditions and harsh environments, construction equipment is susceptible to rust, corrosion, and deterioration. Pressure washing effectively removes corrosive substances, preventing the onset of rust and safeguarding the structural integrity of machinery. By eliminating accumulated grime, it minimizes the risk of damage caused by abrasive particles, preserving the equipment for prolonged use.

Enhancing Safety Standards

Clean equipment contributes to a safer work environment. Removing layers of dirt and debris not only improves the functionality of machinery but also enhances visibility of warning signs, indicators, and critical components. This heightened visibility reduces the likelihood of accidents and malfunctions, promoting a safer workplace for workers.

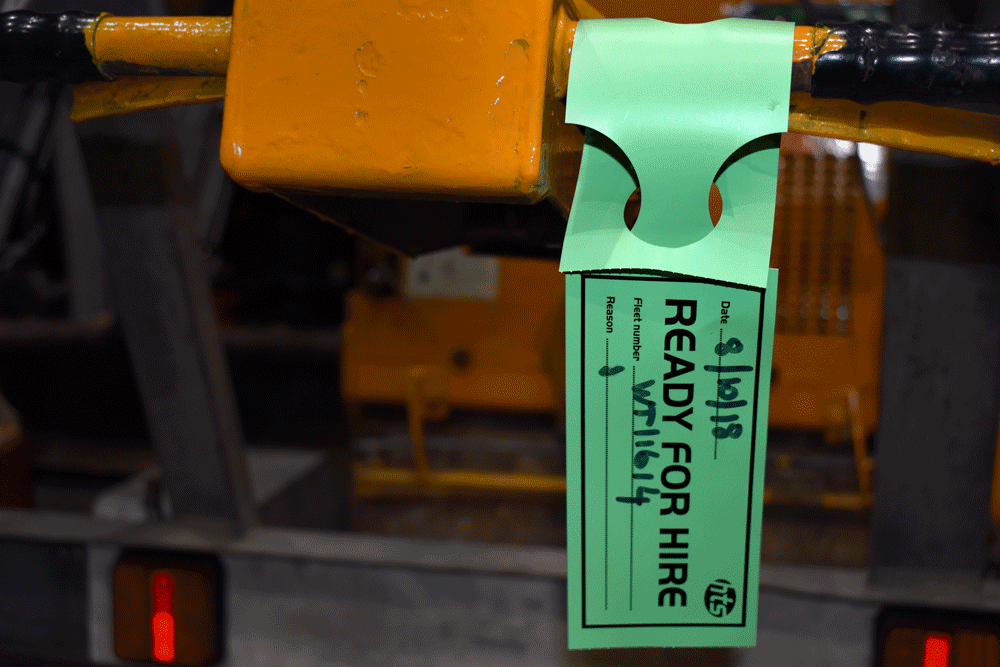

Ensure workers your machine is ready to be used by using our very own Plant Tag, the quickest, easiest and clearest way to tag your plant with a colour coded status label.

Optimising Performance

Efficiently operating machinery is crucial for meeting project deadlines and maintaining productivity. Regular pressure washing ensures that equipment operates at optimal performance levels. Clean machinery experiences reduced friction, operates smoothly, and performs tasks more efficiently, ultimately contributing to project timelines and overall productivity.

Cost-Effectiveness

The cost of repairing or replacing construction equipment due to neglect or improper maintenance can be substantial. Investing in pressure washing equipment is a proactive approach that significantly reduces long-term expenses. Regular cleaning extends the lifespan of machinery, minimising repair costs and downtime.

Here are HTS, we sell a wide range of pressure washers and accessories, including the lances. Whilst the lances can withstand a lot, they are also the most common part on a pressure to break (especially in the winter!) due to accidental damage or if they freeze up, so it's good to keep a few spare on hand!